DTF Transfer Technology Guide: Revolutionize Your T-Shirt Printing Operation in 2025

The DTF transfer method has transformed the t-shirt printing business, providing unmatched versatility and quality for businesses of all sizes. As we move forward in 2025, DTF transfers have become the top choice for generating bright, long-lasting prints on virtually any fabric type. Whether you're a seasoned print shop owner or just starting your venture in bespoke garments, understanding the power of DTF printing technology is crucial for remaining relevant in the current marketplace.

DTF Printing Explained How It Works

DTF printing is an cutting-edge digital printing method that uses creating designs on special PET film using eco-friendly inks and adhesive powder. In contrast to traditional printing methods, DTF transfers can be transferred onto multiple fabric types from natural to synthetic without pre-treatment. This adaptability makes DTF printer technology highly sought-after among companies looking for streamlined, professional printing alternatives.

The method produces prints that are both visually stunning but also exceptionally resilient. DTF transfers withstand cracking, peeling, and fading even after numerous wash cycles, making them excellent for business use where lasting quality is paramount. With the capacity to reproduce intricate designs, gradients, and lifelike pictures, DTF printing provides endless creative possibilities for your company.

The DTF Transfer Process: Complete Tutorial

Creating commercial-grade DTF transfers requires understanding each stage of the process. Here's a comprehensive breakdown:

1. Artwork Development

Start by designing your graphic using professional software like professional design tools, or simpler options like online design platforms. Export your design as a crisp PNG file with a transparent background. The benefit of DTF printing is that you can work with complex, multi-colored designs without concerning yourself with color restrictions.

2. Creating the Transfer

Load your design into the DTF printer program. The printer will initially deposit the color layers (CMYK) directly onto the PET film, followed by a white ink layer that serves as a base. This white layer is crucial for ensuring vibrant colors on dark fabrics. Latest DTF printer models can reach speeds of up to high production rates, making them ideal for mass production.

3. Powder Application

When the ink is still wet, consistently distribute hot-melt adhesive powder across the entire printed design. This powder is what attaches the DTF transfer to the fabric during application. Use a back-and-forth movement to ensure complete coverage, then eliminate any excess powder. Many companies are now acquiring automated powder shakers for consistent results.

4. Curing the Transfer

The adhesive powder needs to be heat-activated before application. This can be accomplished using a specialized oven (recommended for best practices) or by hovering under a heat press. Curing usually takes 60-90 seconds in an oven at the appropriate temperature. Correct curing ensures your DTF transfers can be preserved for later use or used immediately.

5. Heat Press Application

Initially press your garment for 10 seconds to remove moisture and wrinkles. Position your DTF transfer on the fabric and press at 325°F (165°C) for optimal duration with medium pressure. The heat engages the adhesive, forming a permanent bond between the design and fabric.

6. Removal and Finishing

Following application, remove the film while it's still warm in one fluid movement. This warm removal method delivers clean edges and prevents unwanted lines in your design. To finish, perform a second press for another 10-15 seconds to improve durability and minimize shine.

DTF Market Leadership Industry Trends

The DTF printing market has experienced explosive growth, valued at nearly $3 billion in 2024 and expected to reach $3.92 billion by 2030. This outstanding development is powered by several key factors:

Superior Flexibility

In contrast with other printing methods, DTF transfers work on almost every fabric type without pre-treatment. From pure cotton to artificial fabrics, various materials, DTF printing provides consistent, high-quality results across all surfaces.

No Minimum Order Requirements

If you require individual items or thousands, DTF printer technology removes initial expenses and minimum quantities. This versatility makes it perfect for print-on-demand, custom requests, and testing new designs without investment concerns.

Premium Results

Contemporary DTF printing generates incredibly detailed, colorful designs that rival or exceed standard processes. The technology performs best with reproducing photographic images, complex gradients, and fine details that would be challenging with screen printing or vinyl cutting.

Economic Efficiency

With reduced initial investment than screen printing and faster production than DTG printing, DTF transfers offer an outstanding ROI. The capability to group different artwork on a unified transfer additionally minimizes costs and material waste.

Essential Equipment for DTF Printing Success

To start your DTF printing journey, you'll require the following tools:

- Printing Equipment: Pick between dedicated machines by brands like Epson, Roland, and Mimaki, or convert existing printers for DTF printing

- DTF Inks: Formulated textile inks created for best adhesion and color brilliance

- PET Film: Sold in rolls or sheets, with varied peel options

- Bonding Powder: Standard powder for most uses, dark for dark designs on dark fabrics

- Heat Press: Professional press with reliable temperature and pressure

- Heat Tunnel: For optimal powder curing (highly recommended)

- RIP Software: For quality control and print optimization

Industry Developments Shaping 2025

Sustainability Focus

The market is adopting eco-friendly practices with aqueous formulations, biodegradable films, and reduced power consumption. Consumers are increasingly demanding eco-friendly options, making eco-consciousness a competitive edge for DTF printing companies.

Technology Advancement

Advanced DTF printer equipment now feature AI-driven software, automated powder distribution, and smart diagnostics. These innovations minimize operational expenses while boosting uniformity and print quality.

Personalization at Scale

The power to manufacture unique designs at the identical rate as standard designs is revolutionizing the industry. DTF transfers enable businesses to provide true personalization without compromising production speed.

Getting the Most from DTF

To excel with DTF printing, implement these best practices:

- Select high-grade DTF printer equipment and materials for reliable output

- Properly care for your machinery to avoid downtime

- Fine-tune your workflow by ganging designs on single sheets

- Stay updated on technological advances and new DTF printing innovations

- Connect with reliable suppliers for uninterrupted material supply

- Educate staff on proper DTF transfers usage

The Future of DTF Printing

As we move forward, DTF printing continues to evolve with groundbreaking changes. Market analysts anticipate ongoing expansion in industry presence, with DTF transfers establishing as the benchmark for garment decoration.

If you're set to launch your DTF printing venture or seeking to improve your current setup, now is the optimal opportunity to invest in this game-changing technology. With the right machinery, knowledge, and focus, your DTF printer can function as the foundation of a thriving garment decoration enterprise.

Begin Your Journey

Upgrade your operation with commercial-quality DTF transfers. Reach out to discover about our comprehensive lineup of DTF printing solutions and begin producing incredible personalized garments today!

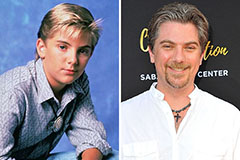

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!